THE IDENTITY OF MORGANTECNICA

A highly qualified crew of engineers, designers, researchers, and renowned experts in the textile industry help us to maintain this level of excellence. Our team of professionals is

available to listen and support you in the realization of your entire project, offering complete, integrated, and customized solutions.

Fashion technology

ONE WORD. FASHIONTECHNOINNOVATION

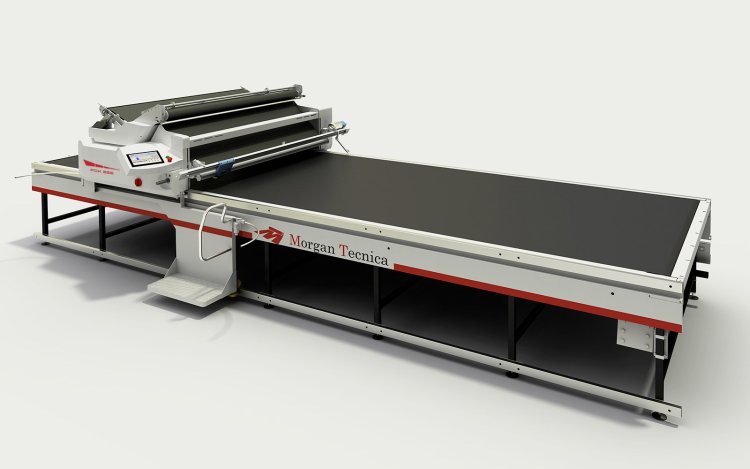

Rex Range

CUTTING IS GREEN TECH

MorganTecnica showcases innovation with the launch of a groundbreaking product on the market: THE “REX” SERIES.The REX Series is a cutting-edge product that places us at the top of the rankings regarding both real and perceived quality.

REX is a revolutionary product boasting remarkable energy efficiency and cutting precision. This machine enables substantial energy savings, with an estimated up to 50% reduction in energy consumption compared to traditional cutting machines within the same range. Experience the future of cutting technology with REX, where innovation meets efficiency.

The spreading machines are equipped with most advanced electronics and software developed ad hoc to allow the best possible control, even by remote. Compact and versatile, the guarantee best performances in the spreading of any type of material. The PC touch on board offers the possibility to control and manage the productivity even by remote.

The spreading machines are equipped with most advanced

- IDEAL FOR REGULAR SERIES PRODUCTION

- COMPUTER TOUCH WITH WINDOWS OS AND WIFI

- IMPROVE QUALITY BY SOLID BELT CRADLE

- INCREASE RELIABILITY WITH AUTO-DIAGNOSIS SYSTEM

The Fox 100 is robust and versatile, but still remaining compact and agile. It is the ideal solution for continuous production of regular lays, even with different types of fabrics, thanks to the possibility to set up and manage several spreading profiles in the on board computer. Every detail has been carefully designed to make the operator feel comfortable: The design is modern and ergonomic and the machine is easy to use, thanks to the interactive computer touch with Windows OS and a software developed ad hoc, according to most modern technics. The cradle turret is with single solid PVC belt (not parallel stripes), which guarantees perfect and even grip throughout the fabric width. Electronically controlled “dancer bar” and encoder for “tension free” spreading and without end-catchers.

All movements are electronically and digitally controlled, with possible multi-function setup, so that every user can actually create and store different profiles, customized for individual needs and material types. The PC Touch with Windows OS and Wifi connection allows remote update and support service. Key words for this new product are: high technology, max reliability, top level performances.

TECHNICAL SPECS: • Max speed 100 m/min. • Width available 180 – 230 cm • Max capacity 100 Kg* • Max roll diameter 50 cm • Voltage 400V 3Ph 50/60 Hz.

(*) Recommended weight in standard working conditions Kg. 60

The Fox 200 has been expressly designed for heavy duty production, with regular lays and even different types of fabrics,

- IDEAL FOR HEAVY DUTY PRODUCTION

- COMPUTER TOUCH WITH WINDOWS OS AND WIFI

- IMPROVE QUALITY BY SOLID BELT CRADLE

- INCREASE RELIABILITY WITH AUTO-DIAGNOSIS SYSTEM

The Fox 200 has been expressly designed for heavy duty production, with regular lays and even different types of fabrics, thanks to the possibility to set up and manage several spreading profiles in the computer on board. The structure has been reinforced, although it remained compact and the designed remained nice and modern. Every detail has been carefully designed to make the operator feel comfortable: The design is modern and ergonomic and the machine is easy to use, thanks to the interactive computer touch with Windows OS and a software developed ad hoc, according to most modern technics. The cradle turret is made with double solid PVC belt (not parallel stripes), which guarantees perfect and even grip throughout the fabric width. Electronically controlled “dancer bar” and encoder for “tension free” spreading and without end-catchers.

An electronic device checks and eliminates in real time the fabric tension, for real tension-free spreading. All movements are electronically and digitally controlled, with possible multi-function setup, so that every user can actually create and store different profiles, customized for individual needs and material types. The PC Touch with Windows OS and Wifi connection allows remote update and support service. Keywords for this new product are: high technology, max reliability, top level performances.

TECHNICAL SPECS: • Max speed 100 m/min. • Width available 180 cm • Max capacity 200 Kg • Max roll diameter 80 cm • Voltage 400V 3Ph 50/60 Hz.

MAX SPEED

100 m/min

MAX ROLL CAPACITY

200 kg

MAX ROLL DIAM

80 cm